Aluminium Handle Profile For Cabinet

Product Description

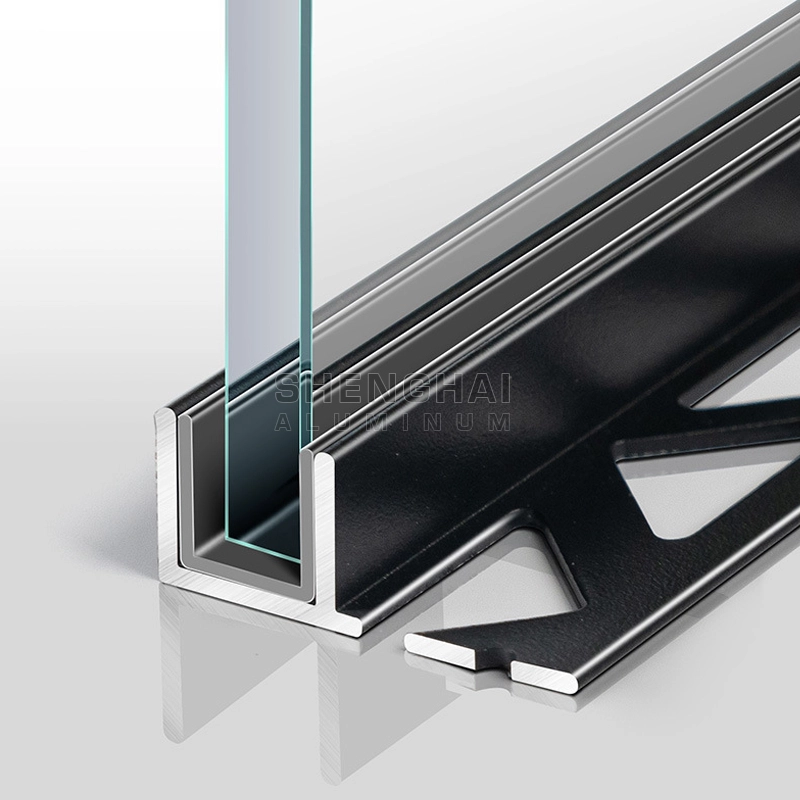

Aluminum profile handles and furniture elevate home décor with their minimalist yet elegant appeal. Today, aluminum profiles are widely favored in construction and interior design, offering a superior alternative to plastic, stainless steel, and wood. Thanks to the inherent advantages of aluminum alloy—lightweight strength, corrosion resistance, and eco-friendliness—they meet the demanding requirements of modern architecture and design.

Among various materials, aluminum profiles stand out for their exceptional cost-effectiveness, combining superior workability, long-lasting durability, and sustainability. The growing popularity of aluminum handles in furniture reflects market trends and consumers’ increasing preference for simplicity, functionality, and aesthetic harmony.

Custom Aluminum Profile Solutions by Sh-Extrusion

As a professional aluminum extrusion manufacturer, we offer OEM services to tailor handle designs to your exact specifications. Our extensive selection includes:

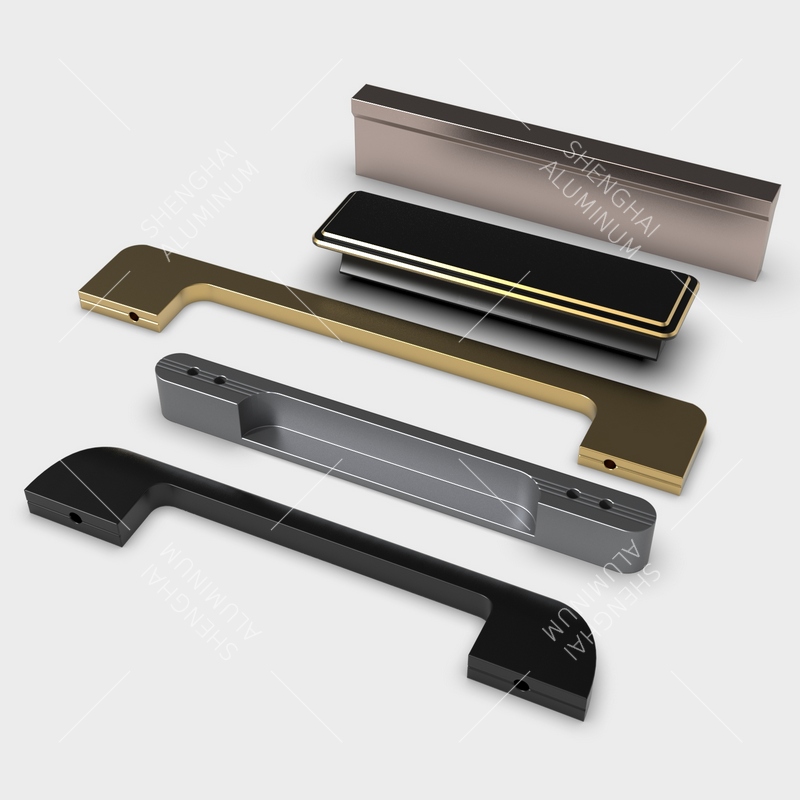

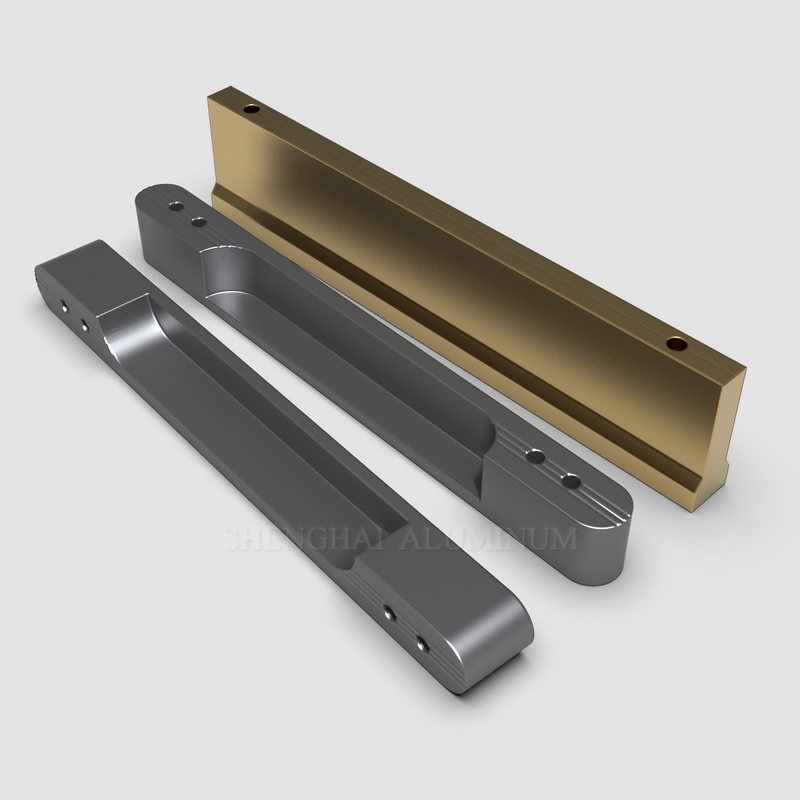

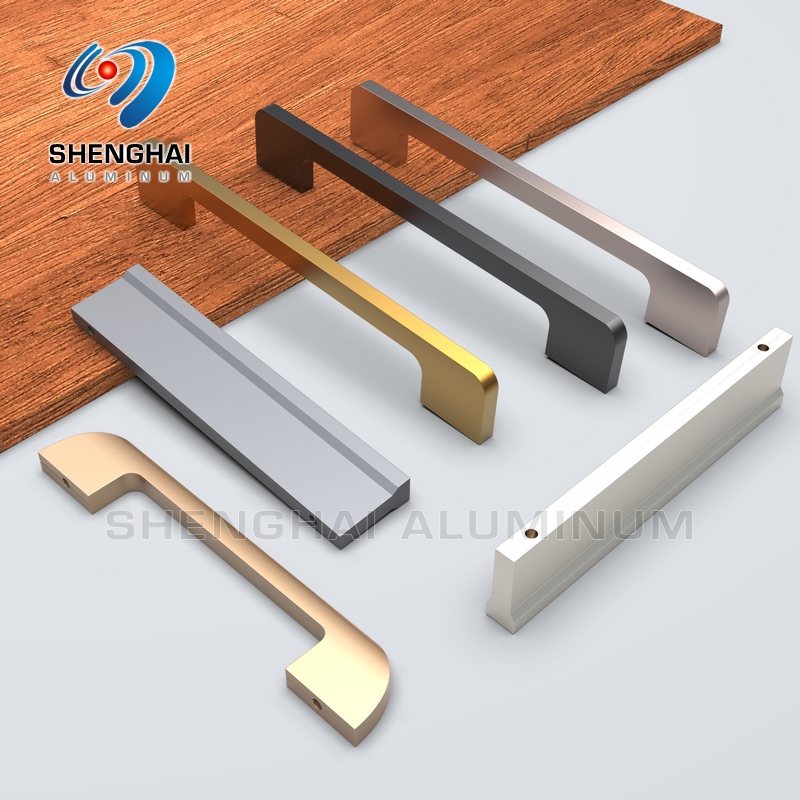

Straight & Bent Aluminum Handles

C-Shaped, G-Shaped & Multi-Component Handles

Handles for Furniture (Drawers, Wardrobes, Cabinets) & Architectural Applications

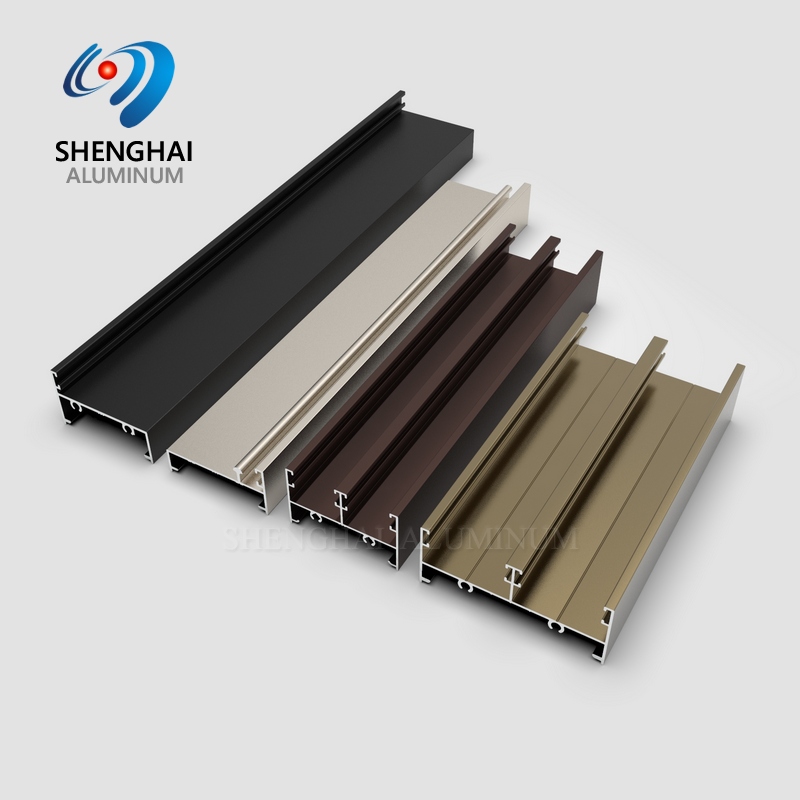

Custom sizing and a variety of anodized finishes (matte, brushed, colored) are available to match diverse project needs.

Product Feature

Product Application

Sh-Extrusion products are widely used in family residences, villas/high-end residences, office buildings/office buildings, hotels/shopping malls, schools/hospitals, airports/stations, factories/warehouses, industries and other scenarios, covering almost all building scene requirements.

The profiles, glass and hardware configurations can be adjusted according to specific scene requirements (such as regional climate, safety level, decoration style, etc.) to achieve the optimal solution.

Packaging Details

PE film for each profile/ Shrink PE film for each bundle, Slot packing, Craft paper/ Foam Paper/Carton box.