How to choose high-quality aluminum profile doors and windows

Aluminum profile folding windows are made of high-quality aluminum alloy materials, exquisitely crafted, and combined with modern design concepts, with excellent structural strength and elegant appearance. Aluminum profile folding windows can provide excellent permeability and lighting effects for your residential or commercial space, and are particularly suitable for balconies, courtyards or large windows, greatly enhancing the sense of openness and lighting effects of the space.

Features of aluminum folding windows

- Space-Saving Folding Design

The folding window can be fully opened when needed, maximizing space utilization and providing an expansive view and improved ventilation. It is particularly suitable for areas with limited space or where flexible window openings are required. - Excellent Thermal and Sound Insulation

The multi-layer sealing design effectively prevents the transmission of external noise and temperature, enhancing indoor comfort. Whether it’s the summer heat or winter chill, the aluminum folding window helps maintain a stable indoor temperature. - Eco-Friendly and Energy Efficient

Our aluminum folding windows meet environmental standards and are made from recyclable materials. With excellent sealing properties, they reduce energy consumption by minimizing the need for heating and air conditioning. - High-Strength Aluminum Frame

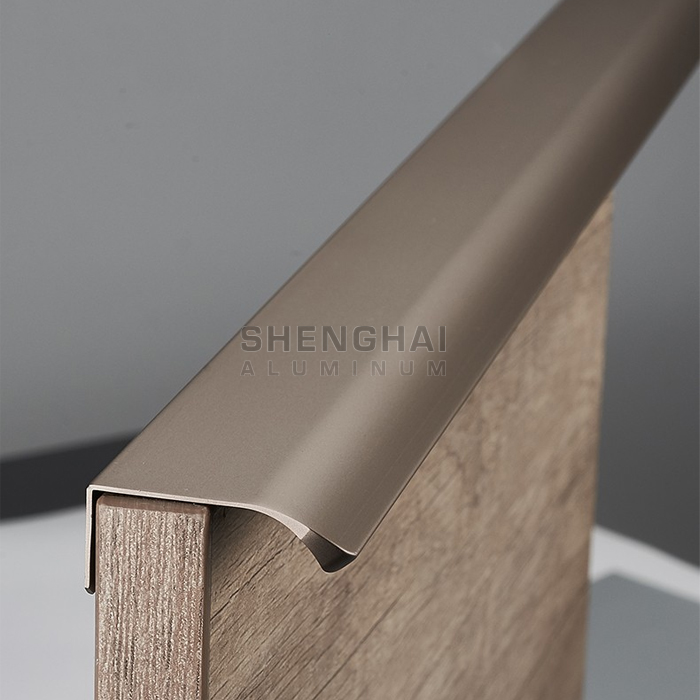

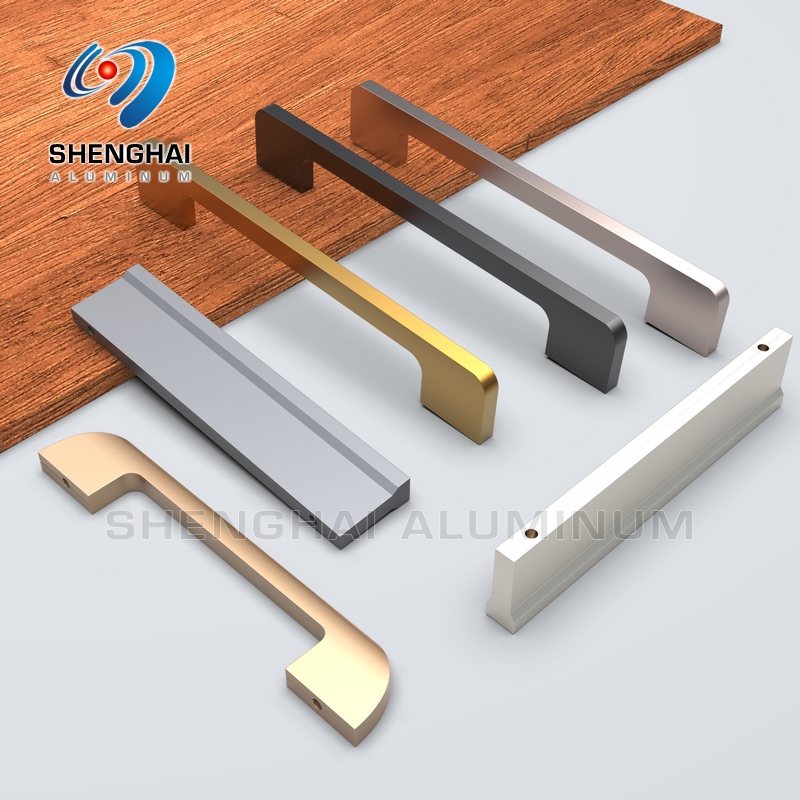

Made from premium aluminum alloy, these windows are strong yet lightweight, ensuring stability and ease of operation. The aluminum frame is specially treated for excellent corrosion resistance, maintaining its performance even in humid or marine climates.

Aluminum profile folding windows not only have a variety of color options, including classic silver, black, white and customized colors, which can be matched with the architectural style according to personal needs, but the surface of the aluminum profile can also be anodized, electrophoretic coated or sprayed to improve corrosion resistance and aesthetics.

These folding windows are not only perfect for modern residences but also highly suitable for commercial buildings, hotels, resorts, and other projects. Their elegant appearance and high efficiency meet the needs of the high-end market, while the economical options make them suitable for various budgets.