The difference between system windows and broken bridge aluminum windows

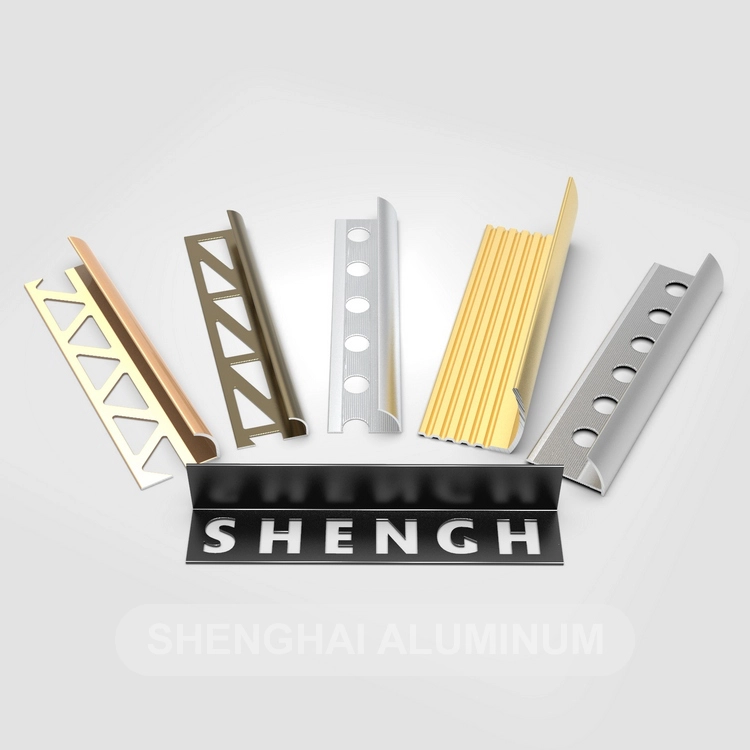

Broken bridge aluminum: This refers to the material itself, which is mainly used to make doors and windows. Broken bridge aluminum doors and windows need to be assembled on site, so it is also called assembled broken bridge aluminum.

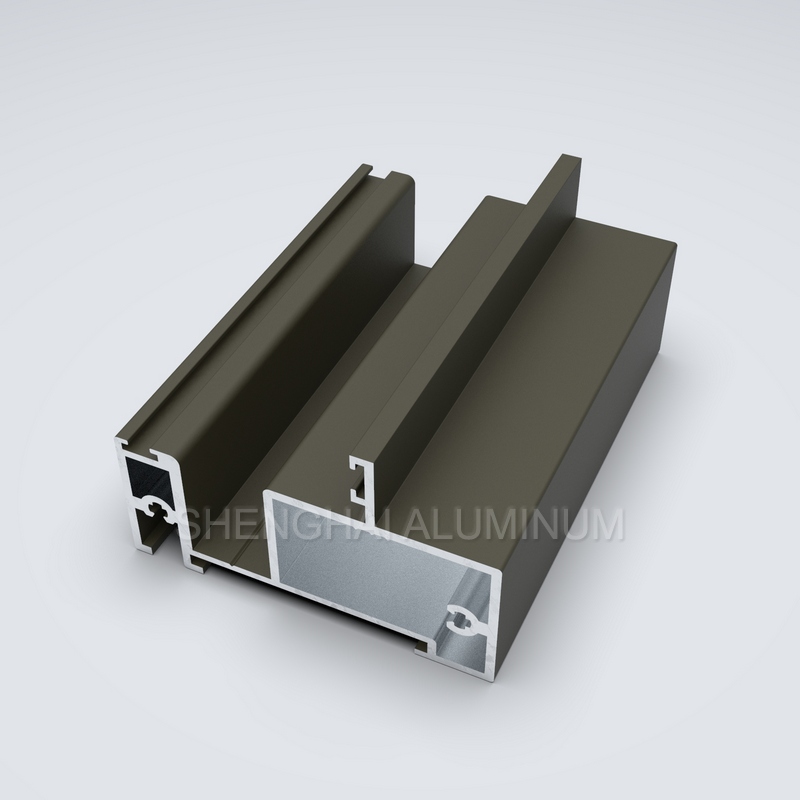

System window: This refers to the production method. The system window completes all the assembly at the manufacturer, and only needs to be fixed and installed on site. Therefore, it is also called system broken bridge aluminum.

How to choose thermally-insulated aluminum doors and windows?

Broken bridge aluminum window: high cost performance, suitable for general living needs.

System window: better performance, suitable for users with high requirements for sound insulation, heat preservation and sealing.

Advantages of system windows and thermally-broken aluminum windows

System windows mainly emphasize customization and high performance, and are suitable for high-end buildings, commercial and residential buildings, emphasizing sealing, heat insulation and sound insulation.

Broken bridge aluminum windows focus on energy saving and heat insulation. Their excellent thermal insulation effect makes them suitable for modern buildings that require energy saving and heat insulation, and they have good wind pressure resistance, waterproofness and durability.

Both have their own advantages, and the choice should be based on the specific needs and budget of the building.

If you need aluminum processing, please feel free to contact us. The engineering team of Shenghai Aluminum will provide you with a customized solution immediately.