When choosing aluminum doors and windows, you can consider the following tips to ensure that you buy the right product.

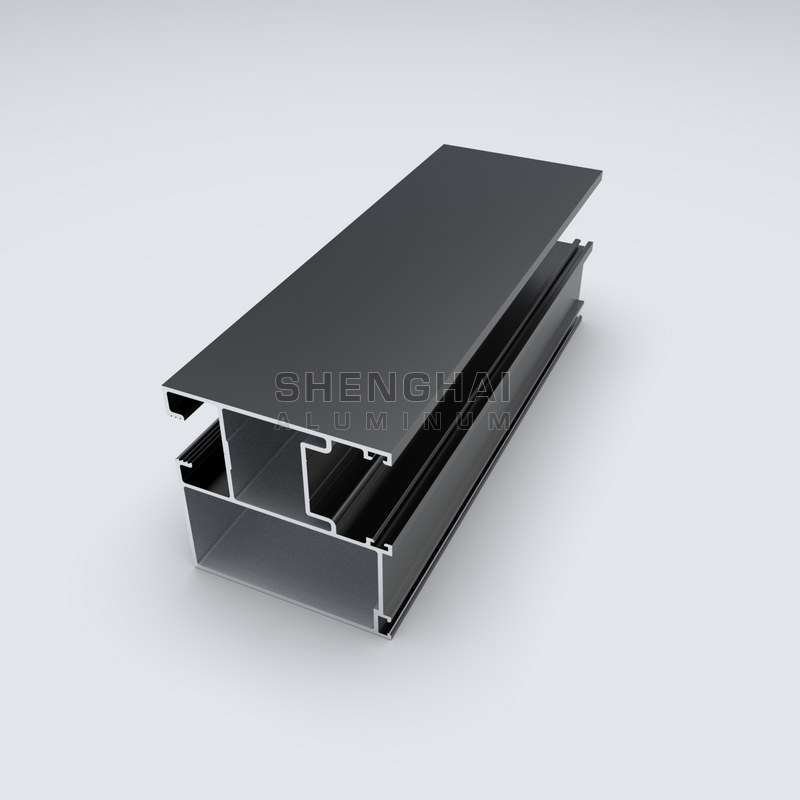

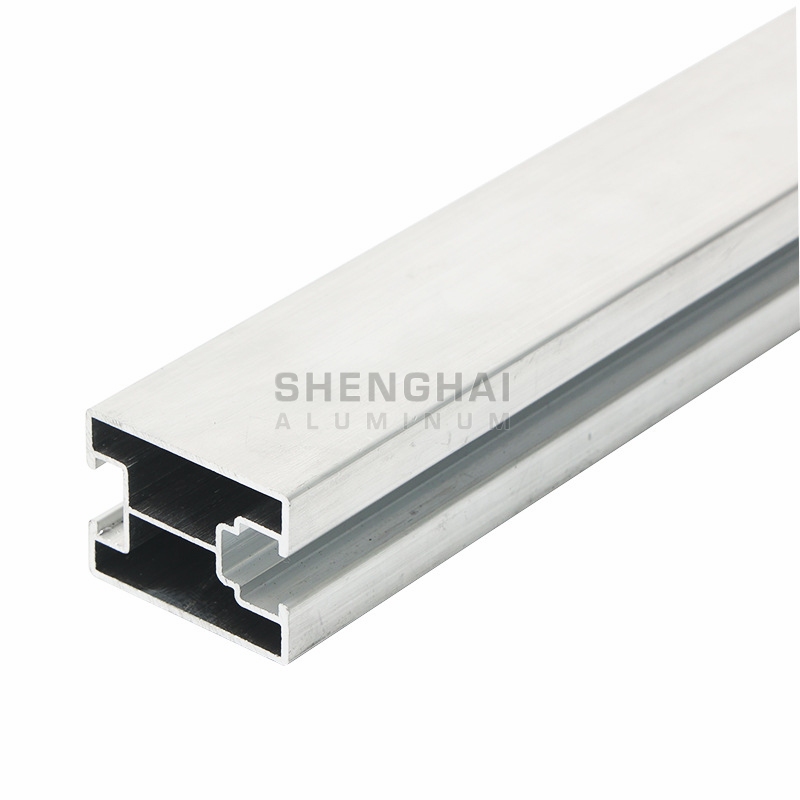

1. You can choose high-quality aluminum alloy materials and check the thickness and specifications of the aluminum. Generally speaking, aluminum with a thickness of 1.2mm and above will be more durable.

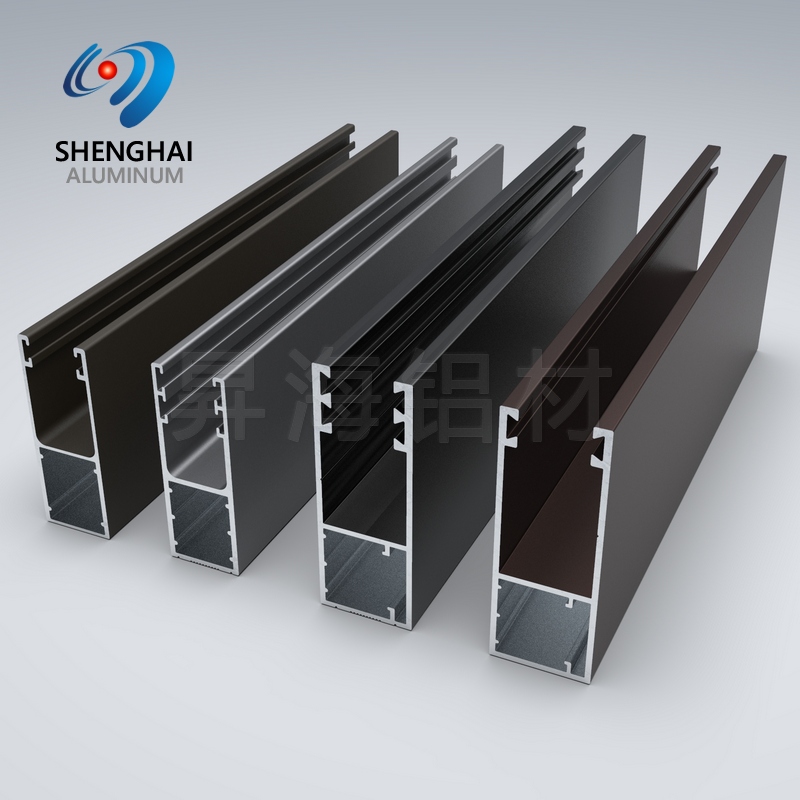

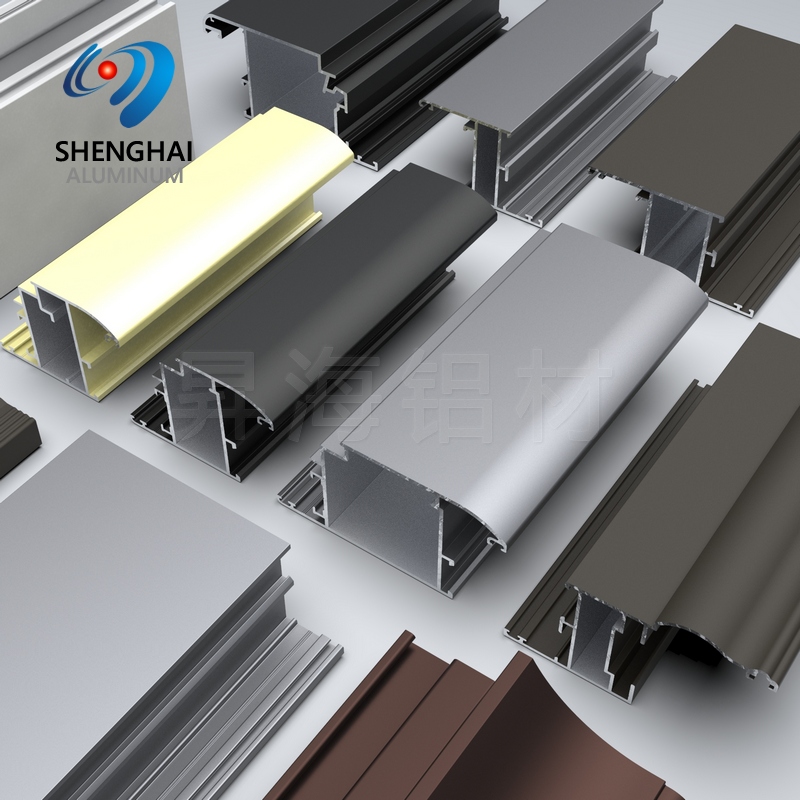

2. When purchasing, pay attention to the surface treatment process of aluminum doors and windows, such as electrostatic spraying, anodizing, etc. These processes can improve the corrosion resistance and weather resistance of aluminum and extend the service life of the product.

3. To ensure that the aluminum doors and windows have good sealing performance, you can check whether there are suitable sealing strips to prevent air and water leakage and improve the sound insulation effect.

4. Choose doors and windows with reasonable structure and scientific design. You can check the structural diagram and load-bearing capacity of the product to ensure its stability and safety.

Features of aluminum doors and windows you must know

- Aluminum doors and windows are made of high-quality aluminum alloy materials, which are lightweight, corrosion-resistant and high-strength. The aluminum alloy undergoes a rigorous surface treatment process, such as anodizing or electrostatic spraying, to enhance its weather resistance and aesthetics, ensuring that the doors and windows maintain a good appearance in all environments.

- Aluminum doors and windows have good thermal insulation properties, which help reduce indoor temperature changes and reduce energy consumption for air conditioning and heating. They are an ideal choice for energy saving and environmental protection.

- Aluminum doors and windows are extremely durable and not easy to rust, deform or fade. They only need regular cleaning and maintenance to maintain their appearance and performance, and their service life can reach more than 20 years.

- Aluminum doors and windows have undergone rigorous safety tests and are adaptable to various climatic conditions to ensure everyone’s safety during use. They are widely used in residential buildings, commercial buildings, industrial buildings, etc.

- It provides a variety of opening methods, including sliding, opening horizontally, folding, etc., which can be selected according to actual needs and space. It is convenient, flexible, beautiful and practical.