Aluminum PV Solar Panel Frame

Product Description

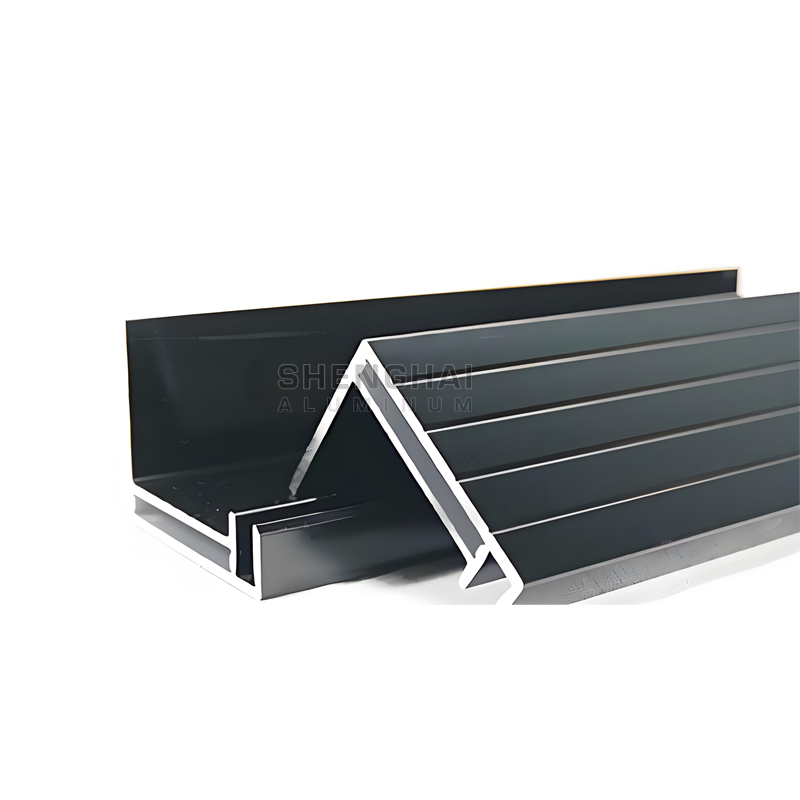

Aluminum Extrusion Frames for Photovoltaic Solar Systems

The aluminum extrusion frame is a critical component in photovoltaic (PV) solar systems, providing essential structural support to ensure the stable operation of solar panels.

Why Choose 6063 Aluminum Alloy?

Our aluminum solar frames are primarily extruded from 6063-grade aluminum alloy, known for its excellent corrosion resistance, strength, and hardness—making it the ideal material for PV applications.

Surface Treatment & Color Options

To enhance durability and performance, our frames are typically anodized in silver white or black. These finishes not only improve corrosion resistance and heat dissipation but also maintain a sleek, functional appearance.

Why Partner with Sh-Extrusion?

6+ years of expertise in the photovoltaic industry

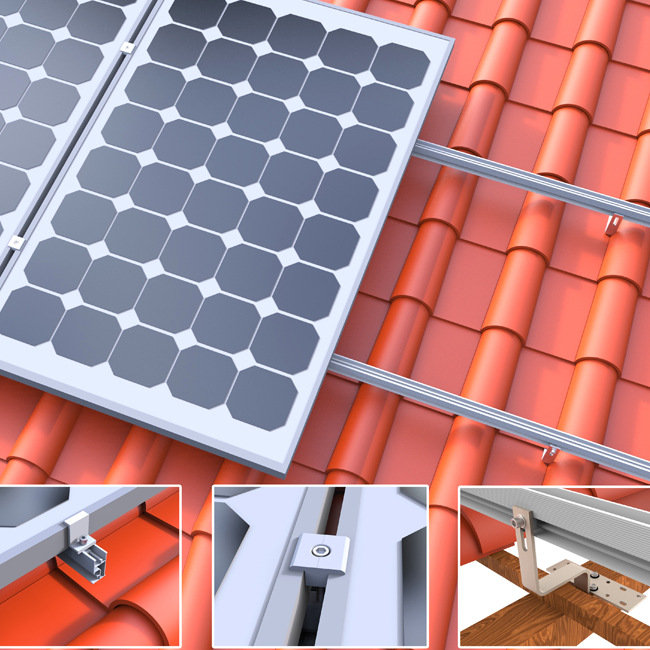

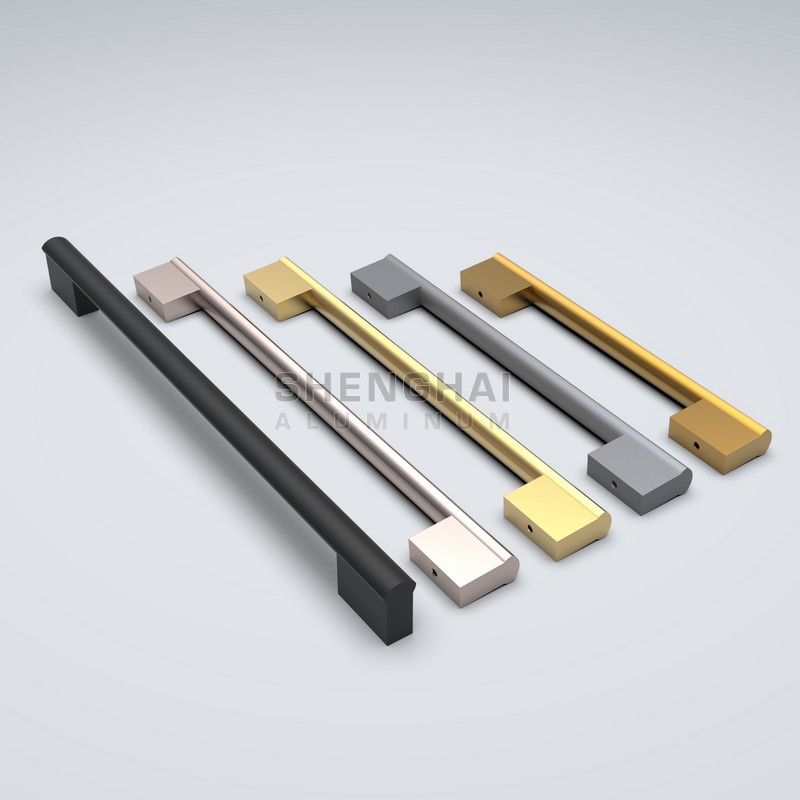

Comprehensive solutions, including aluminum solar frames, PV panel rails, and clamping accessories

Ready-made molds available to reduce lead time and costs

Custom design & mold fabrication services for specialized requirements

We combine efficiency and customization to meet your solar framing needs. Contact us today for high-quality, reliable PV solutions!

Product Feature

Product Application

Sh-Extrusion products are widely used in family residences, villas/high-end residences, office buildings/office buildings, hotels/shopping malls, schools/hospitals, airports/stations, factories/warehouses, industries and other scenarios, covering almost all building scene requirements.

The profiles, glass and hardware configurations can be adjusted according to specific scene requirements (such as regional climate, safety level, decoration style, etc.) to achieve the optimal solution.

Packaging Details

PE film for each profile/ Shrink PE film for each bundle, Slot packing, Craft paper/ Foam Paper/Carton box.