Aluminium Solar Panel PV Mounting Rail

Product Description

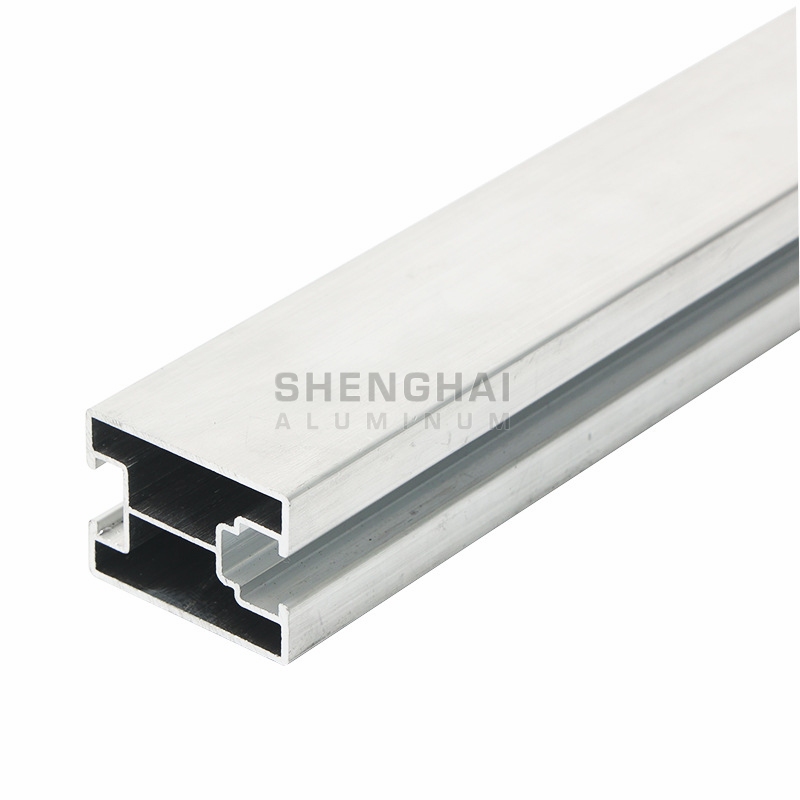

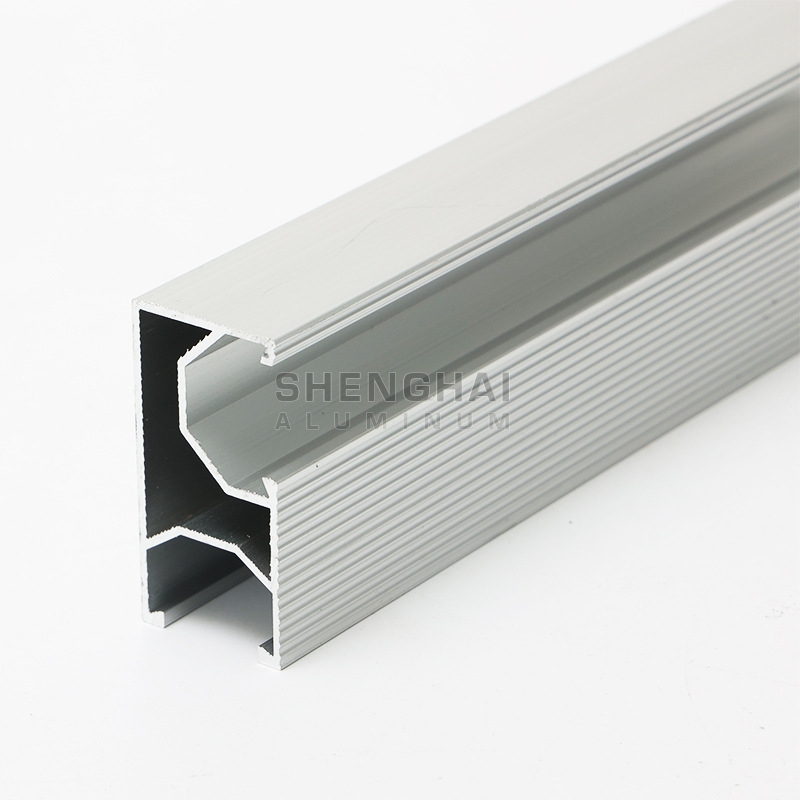

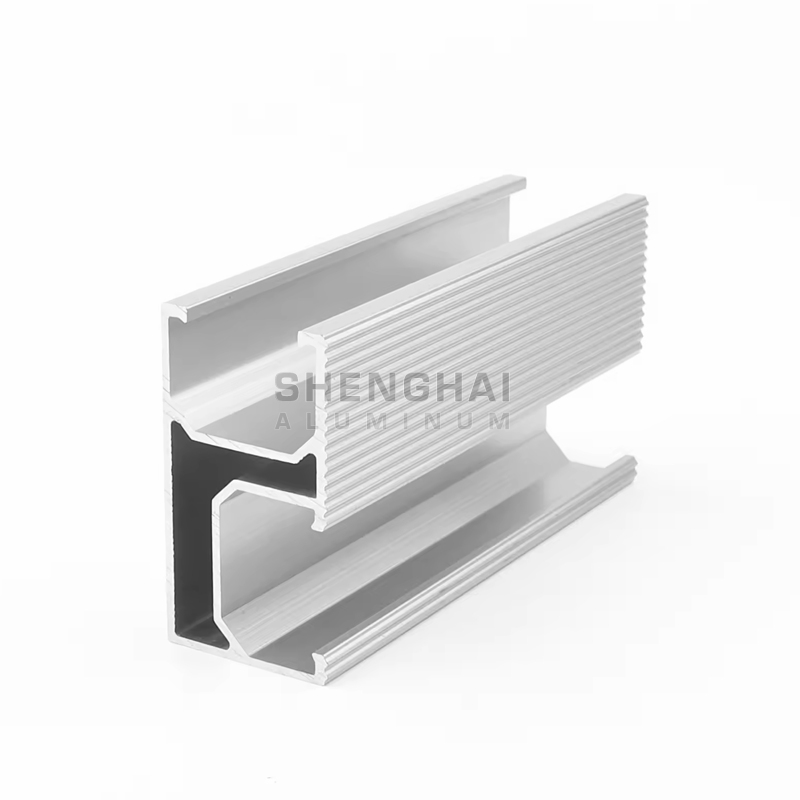

Aluminum Profiles for Solar Applications

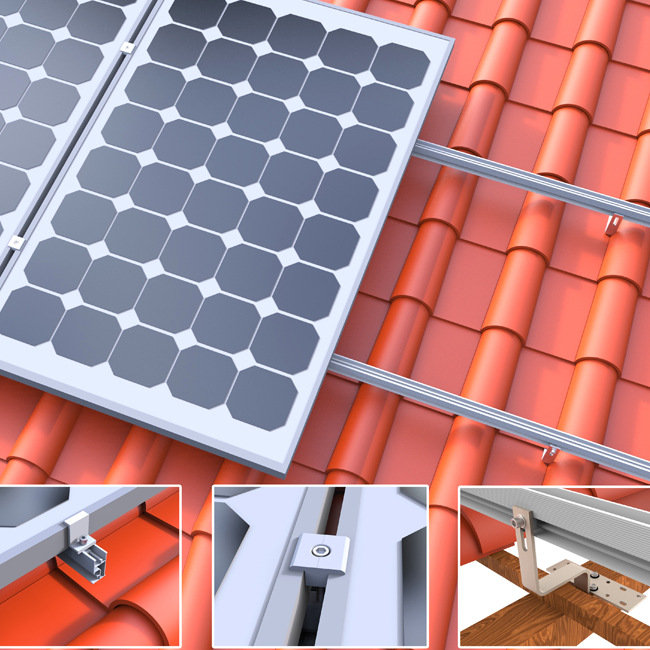

Aluminum profiles offer excellent corrosion resistance, high strength, superior thermal conductivity, and outstanding processing performance. As a standard component in solar panel systems, they serve as one of the key materials in photovoltaic (PV) energy solutions. Aluminum PV mounting brackets are critical elements in photovoltaic power plants, providing essential structural support for solar modules and playing a vital role in maximizing the efficiency of solar energy utilization.

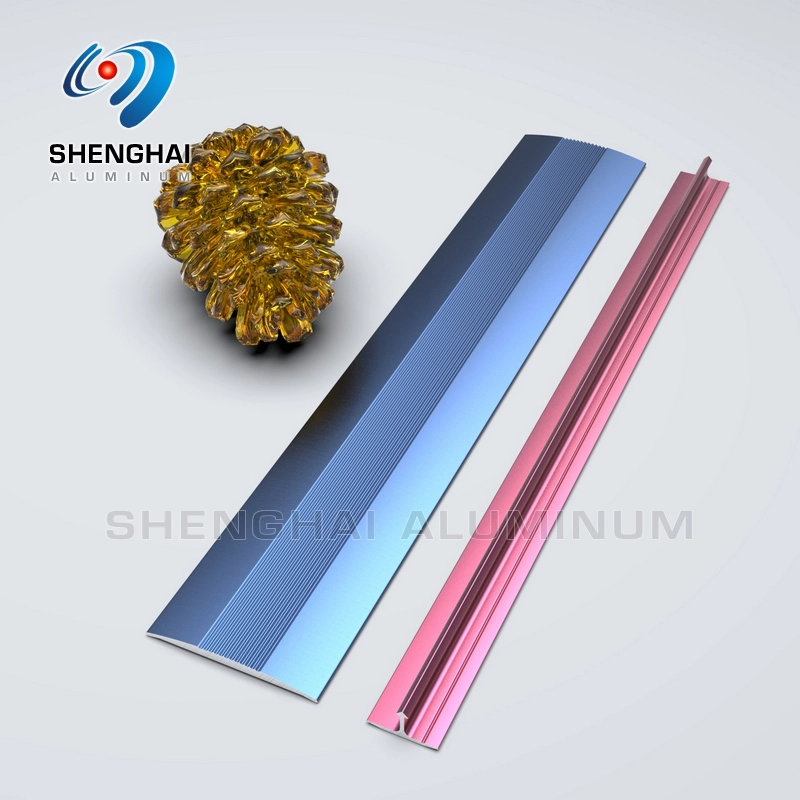

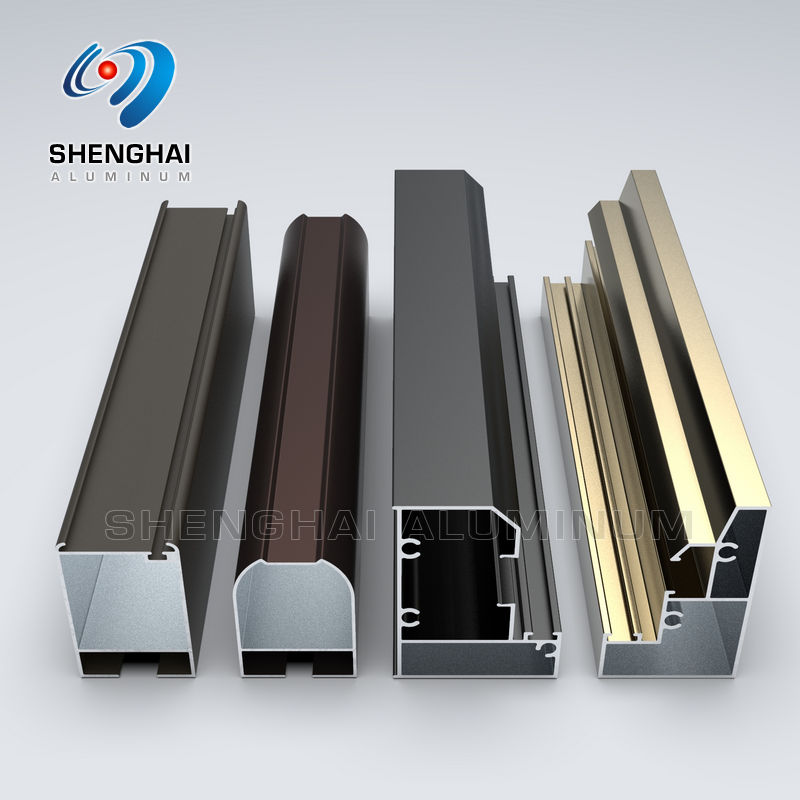

Our aluminum solar panel PV rail brackets are extruded from high-grade aluminum alloy and typically feature anodized surface treatment for enhanced resistance against outdoor oxidation and corrosion. Based on adjustability, PV mounting brackets can be categorized into:

Fixed PV brackets

Adjustable PV brackets

Tracking PV brackets

Given their critical function, PV brackets must meet stringent requirements for stability, load capacity, and safety performance.

Why Choose Sh-Extrusion?

With extensive expertise in solar photovoltaic aluminum profiles, we serve clients worldwide, including the Netherlands, Australia, and New Zealand. Whether you need solar aluminum frames, PV mounting brackets, or custom solar panel accessories, we provide tailored solutions to meet your project needs.

Contact us today to discuss your requirements!

Product Feature

Product Application

Sh-Extrusion products are widely used in family residences, villas/high-end residences, office buildings/office buildings, hotels/shopping malls, schools/hospitals, airports/stations, factories/warehouses, industries and other scenarios, covering almost all building scene requirements.

The profiles, glass and hardware configurations can be adjusted according to specific scene requirements (such as regional climate, safety level, decoration style, etc.) to achieve the optimal solution.

Packaging Details

PE film for each profile/ Shrink PE film for each bundle, Slot packing, Craft paper/ Foam Paper/Carton box.