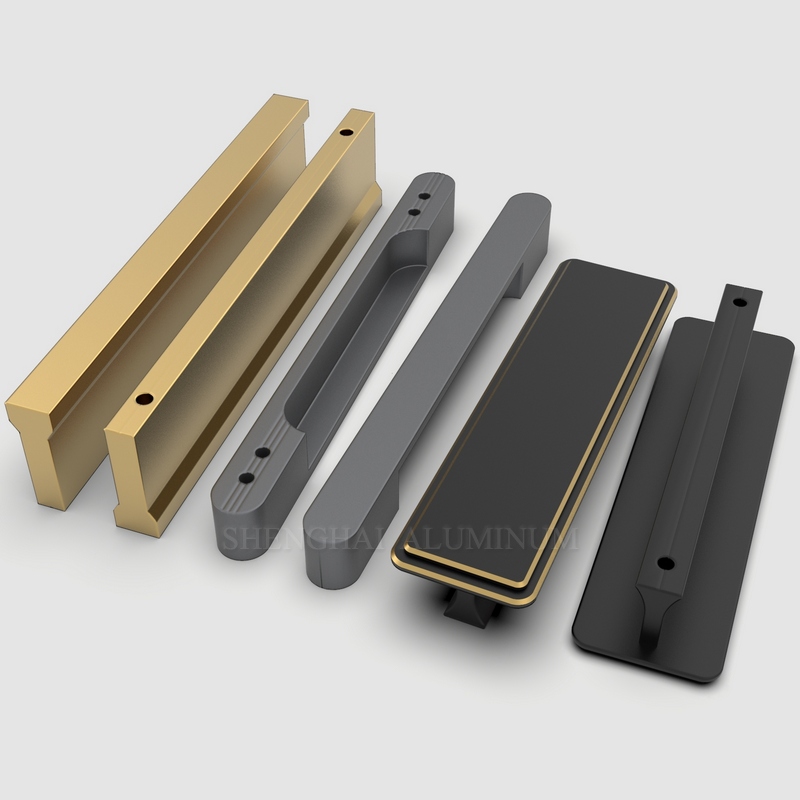

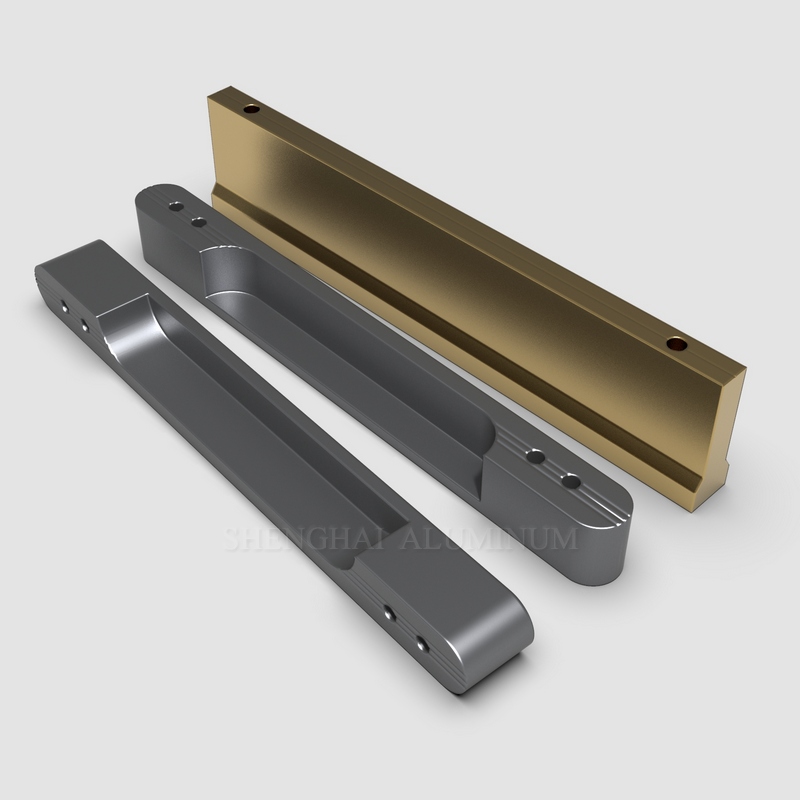

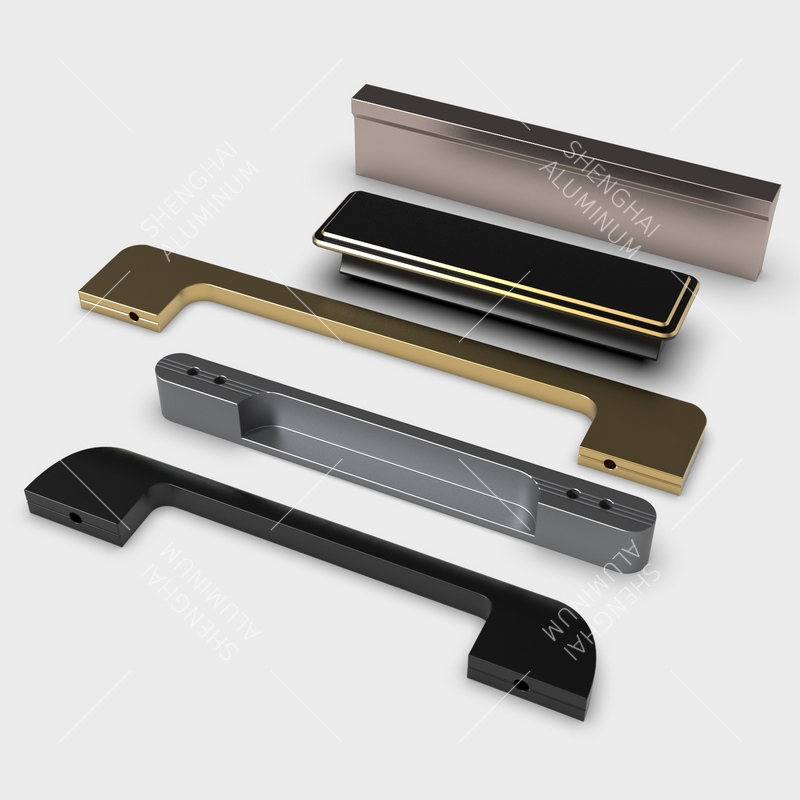

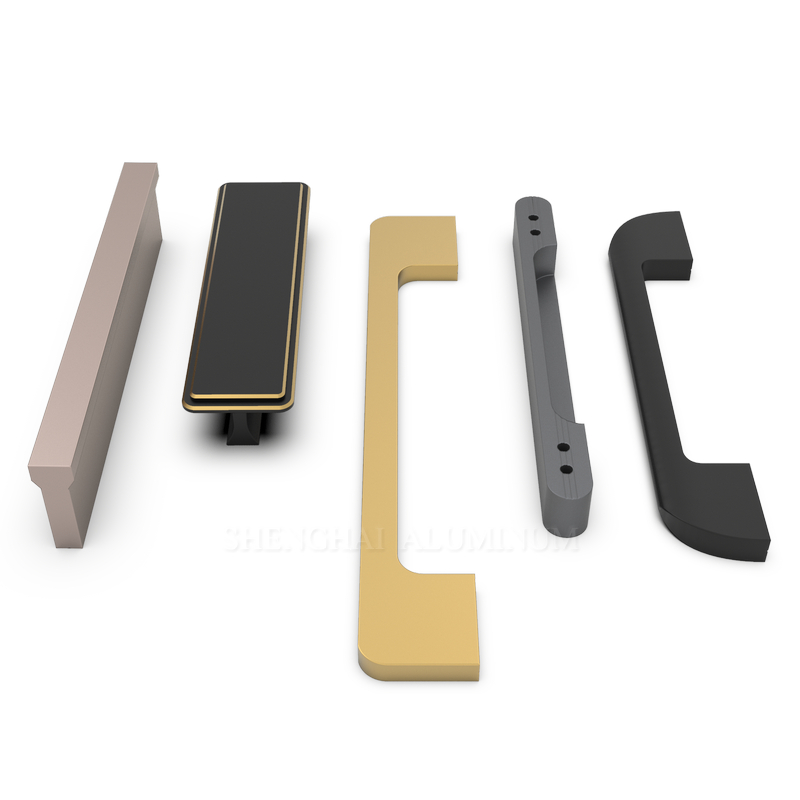

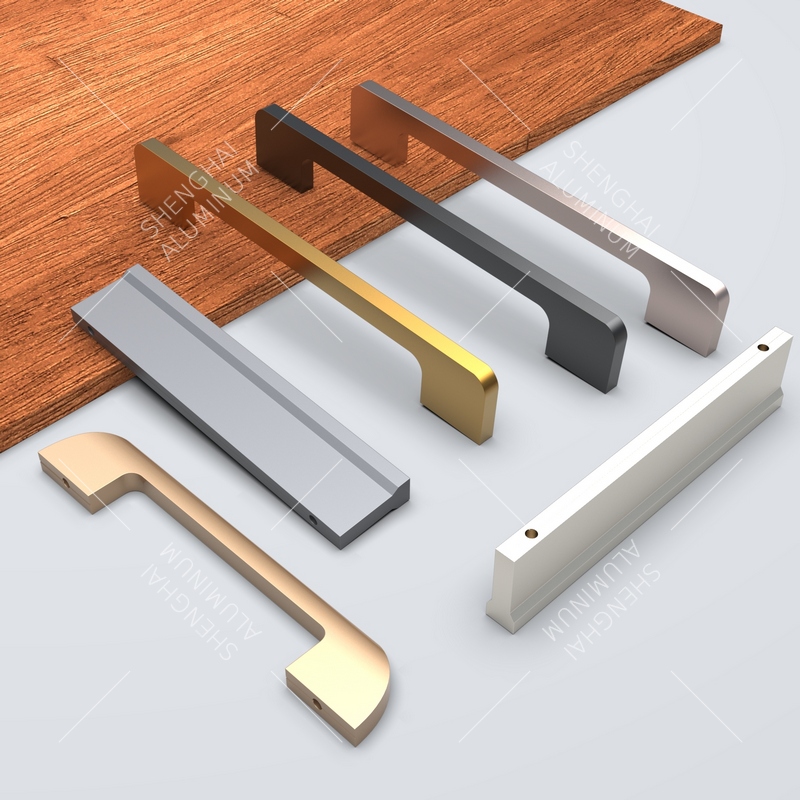

An aluminum profile handle is a type of handle made from aluminum alloy. The material is formed through extrusion, and the handles come in various appearances, such as straight, curved, and arched. They are both aesthetically pleasing and elegant, and are suitable for a wide range of applications, including cabinet doors, drawer doors, sliding doors, and many other scenarios.

Which alloy materials are used for aluminium alloy handle

6063 aluminium alloy: The preferred type of aluminium alloy, containing magnesium and metallic silicon elements. Due to the proportion of these two elements, 6063 maintains better fluidity during the aluminium profile extrusion process. It can easily extrude the shapes required for aluminium handles with complex cross-sectional types and consumes less energy than other alloy materials. Therefore, 6063 is more suitable for the extrusion process and is more suitable as a material for furniture handles.

6061 aluminum alloy: Like 6063, it contains two metallic elements, magnesium and silicon. It has higher strength but also higher energy consumption. Due to its superior compressive and tensile strength, 6061 is more suitable for industrial equipment and is a secondary choice for aluminum handle materials.

How is aluminum profile handle produced

The common production processes for aluminum profile handles include extrusion, die-casting and stamping. Although die-casting can achieve thinner wall thickness, the overall cost is higher and the strength is not as good as extruded aluminum. Stamping is more suitable for standard and simple straight handles, but it is not suitable for producing materials with complex cross-sections. However, it can be mass-produced and has a low cost. Extrusion can complete the production of high-precision and complex cross-section aluminum profile handles, with moderate processing costs and relatively smooth handles after extrusion. In conclusion, extrusion is the most suitable production process for aluminum handles. Next, we will introduce how aluminum profile handles are produced by extrusion.

Preparation and processing of aluminum rods

Aluminum rod preparation: Before processing, the aluminum rods need to undergo composition and appearance inspections. In terms of composition, it is necessary to ensure the accuracy of the aluminum alloy model used and the chemical element composition (such as magnesium, aluminum, and silicon) to avoid excessive impurities that may cause the alloy product to be substandard. These impurities can easily cause porosity, cracks, and other problems. In terms of appearance, it is essential to guarantee the quality of the product and avoid defects such as scratches, bubbles, and obvious oil stains.

Aluminum bar cutting and heat treatment: Cut the aluminum bars into short bars of equal length and arrange them evenly. Then the heating process can be carried out. During the cutting process, the speed should be uniform to avoid inconsistent cutting and length errors. Heating should be done at a uniform temperature to prevent local overheating. The aim is to make the extrusion process smoother and increase the extrusion speed.

Mold heating

Compared with the molds of other common aluminum profiles, the molds for aluminum profile handles are more complex and have a multi-cavity structure. The temperature difference between the aluminum bar and the mold should not be too large to prevent the mold from cracking or deforming, which is due to the relatively large thermal stress. Therefore, the mold needs to be preheated and kept warm for more than two hours.

Cooling and straightening

Cooling: After the extrusion of aluminum profiles, a wind cooling quenching process is required. The main purpose is to enhance the strength and hardness of the handle material, facilitating subsequent aging treatment.

Straightening: When the traction machine pulls the aluminum profiles, it should maintain a uniform speed, especially for complex handle aluminum profiles. The speed should not be too fast to ensure that the extruded handle shapes are uniform and qualified. The purpose of straightening is to correct the unevenly extruded handle aluminum profiles.

Cutting

The cutting of aluminium profiles is also an important step to ensure uniform dimensions. The aluminium profiles for handles should be placed evenly and at consistent intervals. The cutting of aluminium profile handles has high dimensional accuracy.

Aging treatment

Aging treatment can be divided into artificial aging and natural aging, with artificial aging being the common practice. The purpose of aging treatment is to further increase hardness, and the durability of aluminum alloy handles also benefits from this crucial step.

Surface treatment

Surface treatment is a key point in enhancing the corrosion resistance of the handle and also determines the appearance of the aluminum alloy handle. Common surface treatments include powder coating. Powder spraying can significantly enhance the corrosion resistance of aluminum alloy, thus making it suitable for humid and bacteria-rich environments such as kitchens, bathrooms, and toilets.

What are the advantages of aluminum handle

Aesthetic and space-saving

Compared with traditional handles, some aluminum profile handles are more space-saving. For example, concealed aluminum profile handles can be embedded in the door, such as the doors of drawers, cabinets and wardrobes. These handles can blend perfectly with the cabinet doors, presenting a minimalist look that is both beautiful and high-end, while also saving space to a certain extent.

Smoothness and Anti-corrosion Properties

Due to the material characteristics of aluminum alloy handles, their surfaces are relatively smooth, providing a comfortable touch and being less prone to dust accumulation, which makes them easier to clean. The surface treatment of aluminum alloy not only maintains the smoothness but also effectively protects its anti-corrosion performance. Even in damp environments such as kitchens, bathrooms, and washrooms, aluminum alloy handles can well maintain their anti-corrosion properties.

Durable

Aluminum profiles are a lightweight, strong, and corrosion-resistant metal material. This also makes aluminum profile handles very durable. They can remain free from corrosion and damage for a long time. Even if they are damaged, it is only the sealing strip that loses its stickiness, and they can still be well maintained.

The application of aluminum alloy handle

Closet: The style of the handles can adapt to various surface treatment colors and match multiple decorative styles, such as minimalist style, light luxury style, industrial style, new Chinese style, Nordic style, etc.

Cabinets: Kitchen cabinets with aluminum alloy handles can achieve the functions of anti-bacterial and anti-mold, which are very suitable for the damp and greasy environment in the kitchen. They can be used for a long time without any chemical changes.

Drawer:The feature of zero formaldehyde emission of the aluminum handle of the drawer is very suitable for the home environment, especially for environments like the study where drawers are common furniture.

Customized aluminum profile handle

The cross-sectional shapes of aluminum profile handles are diverse, and their appearance and dimensions vary depending on the environment. Therefore, it is best to customize aluminum profile handles. To find a good supplier of aluminum profile handle, Shenghai Aluminum is a manufacturer with 15 years of production experience, capable of providing reliable aluminum profile products. Whether it is the cross-sectional shape, surface treatment or size, we can design and produce according to the provided customization requirements. We are your best choice.