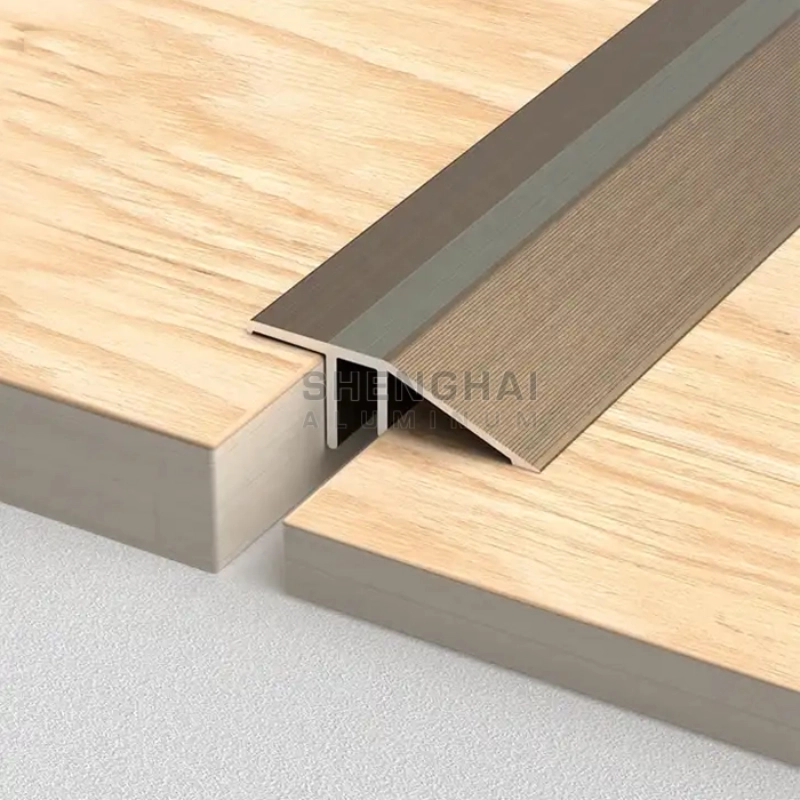

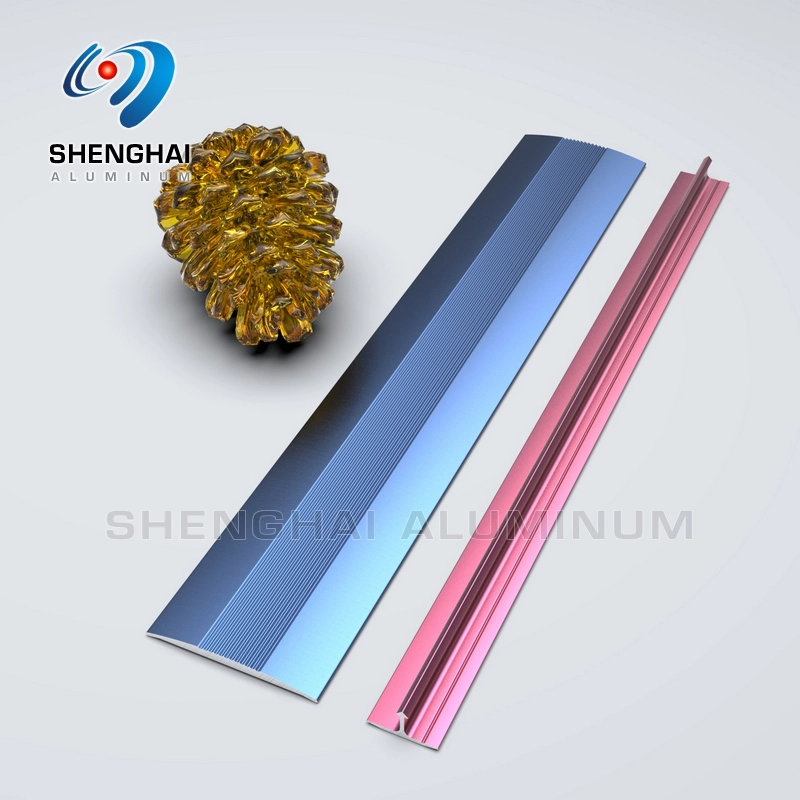

Durable Aluminum Edge Molding

Product Description

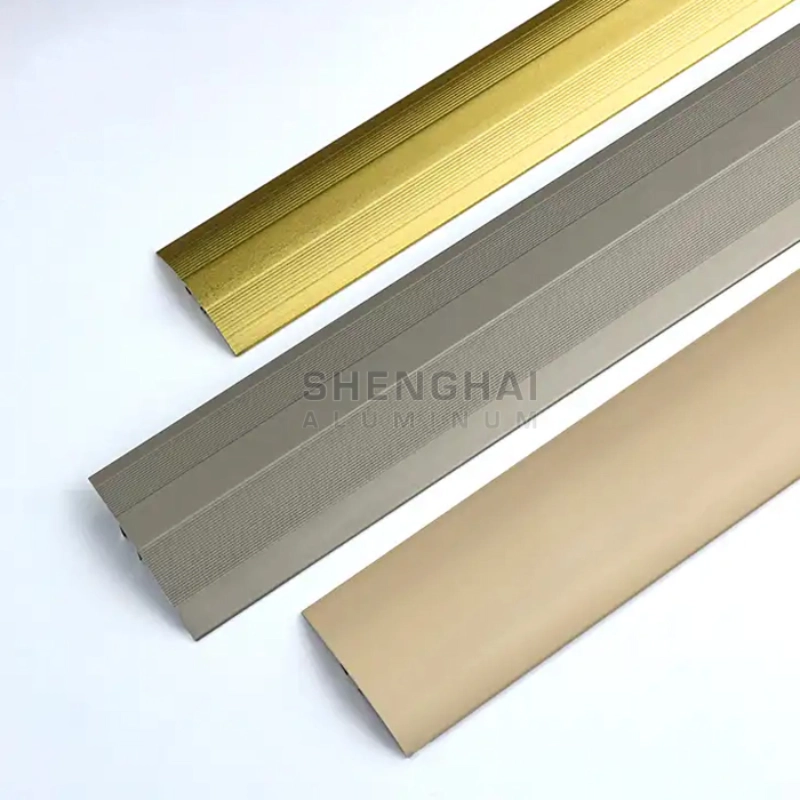

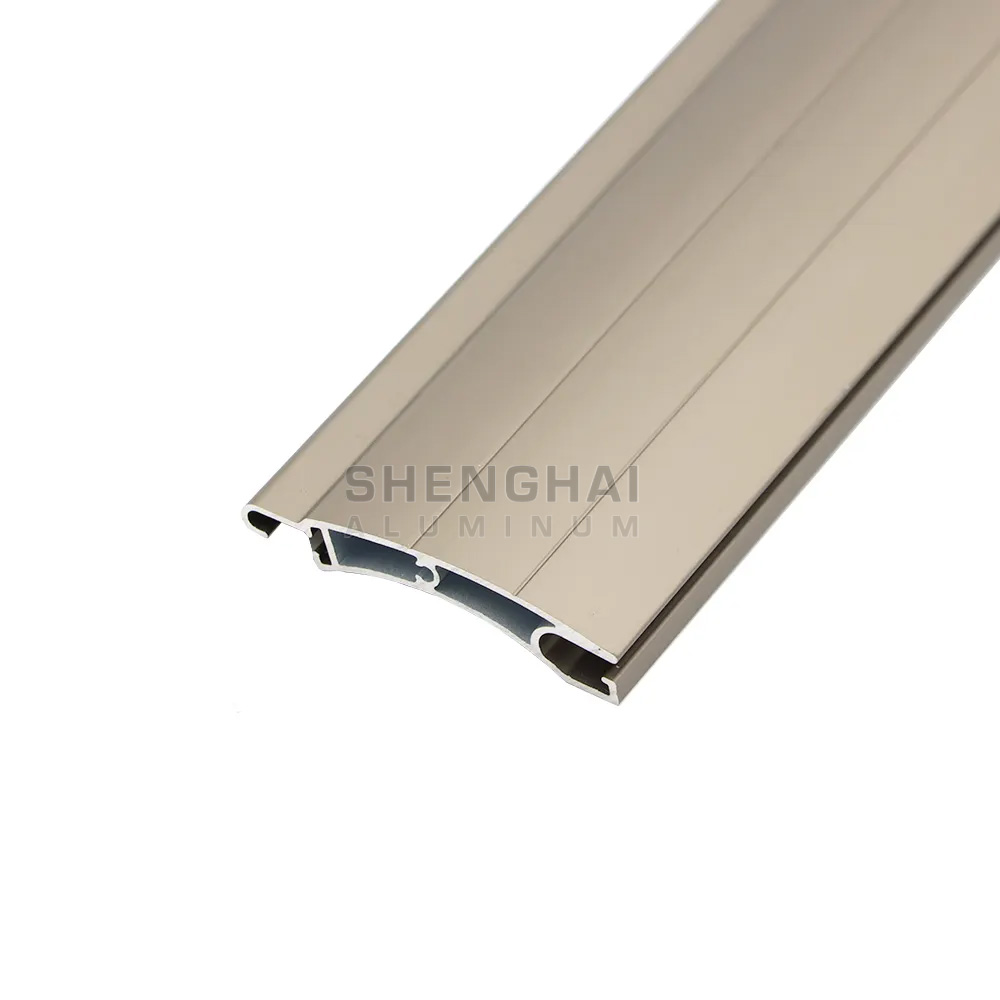

Our aluminum trims are made of high-quality aluminum alloy materials with excellent durability and corrosion resistance. They are widely used for decoration and edge protection in home, commercial and industrial spaces. Surface treatments include processes such as anodizing and brushing to ensure beautiful and long-lasting durability.

Aluminum alloy materials are extremely resistant to corrosion and weathering, and can adapt to various environmental conditions, especially high humidity and high temperature environments. Whether it is used in homes, commercial spaces, or outdoor uses, aluminum trims can maintain their appearance and performance for a long time, avoiding rust and wear.

Our products focus on reducing energy consumption during the production process and ensuring the sustainable use of materials. Choosing aluminum alloy trims can not only enhance the beauty of the space, but also meet environmental needs. We can also customize according to specific needs to ensure that every customer can find a decorative solution that perfectly matches their unique vision.

Product Feature

What we can provide for you

Technical optimization: We can provide professional improvement suggestions for your products to ensure that the design is more in line with market demand.

Strict quality control: We are equipped with experienced quality inspectors to strictly control every production detail to ensure product quality and compliance.

Color and sample customization: We can provide you with personalized color matching services to ensure that the product fully meets your brand needs.

Mold design and development: We have strong mold development capabilities and can customize according to customer needs to meet different product requirements.

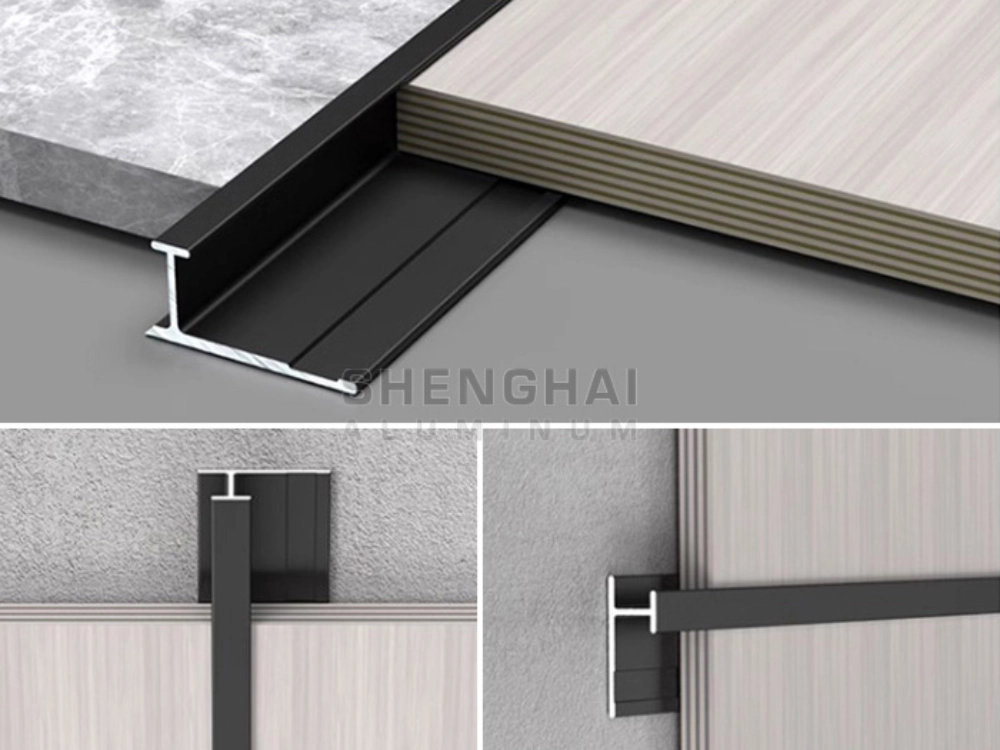

Product Application

Sh-Extrusion aluminum products are widely used in family residences, villas/high-end residences, office buildings/office buildings, hotels/shopping malls, schools/hospitals, airports/stations, factories/warehouses, industries and other scenarios, covering almost all building scene requirements.

The profiles, glass and hardware configurations can be adjusted according to specific scene requirements (such as regional climate, safety level, decoration style, etc.) to achieve the optimal solution.

Packaging Details

PE film for each profile/ Shrink PE film for each bundle, Slot packing, Craft paper/ Foam Paper/Carton box.