Why Aluminum Extrusions Are Used in Solar Panel Designs

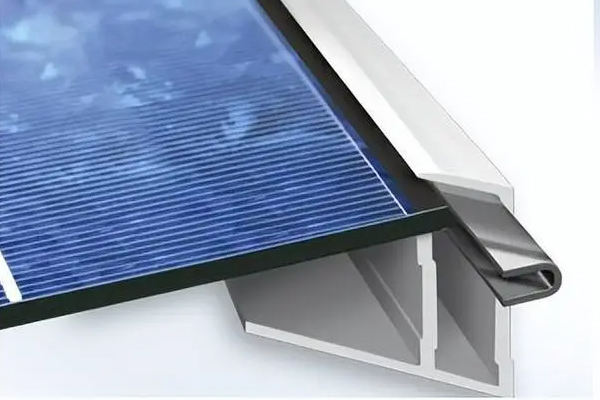

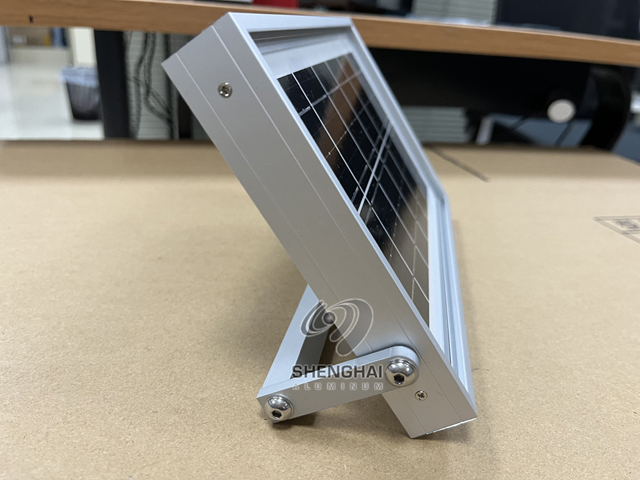

Aluminum brackets have become an indispensable key component in solar photovoltaic systems due to their high strength, corrosion resistance, excellent thermal conductivity, and environmental protection. It not only ensures the long-term stable operation of the system, but also reduces maintenance costs and improves installation efficiency, perfectly meeting the needs of solar energy systems.

Aluminum is easy to process into various shapes and sizes, and the bracket structure can be customized according to different installation requirements, and flexibly adapted to various installation scenarios, such as rooftop and ground installation. Aluminum brackets can not only meet personalized needs, but also reduce the complexity and cost of production and installation.

Aluminum solar bracket: ideal choice for high efficiency, durability and environmental protection

1. High strength and light weight

Aluminum has a very high strength-to-weight ratio, which can provide sufficient support while remaining light. For solar photovoltaic systems, the bracket needs to bear the weight of the solar panel and external pressure (such as wind, snow, etc.). The high strength of aluminum allows the bracket to stably support the solar panel, and its light weight makes installation easier.

2. Excellent corrosion resistance

Aluminum itself has a natural oxide protective layer, which makes it have excellent corrosion resistance and is particularly suitable for outdoor environments, especially areas with heavy humidity or near the ocean. Aluminum brackets can resist corrosive substances such as salt spray and acid rain, ensuring stable performance during long-term use and extending the service life of solar energy systems.

3. Excellent thermal conductivity

Aluminum has good thermal conductivity and can effectively reduce the operating temperature of solar panels. This is very important for improving the efficiency of solar panels, because excessive temperature will cause the efficiency of photovoltaic modules to decrease and even affect their long-term service life. Aluminum brackets help dissipate heat and improve the energy conversion efficiency of the entire system.