Aluminum Solar Panel Mounting Bracket

Product Description

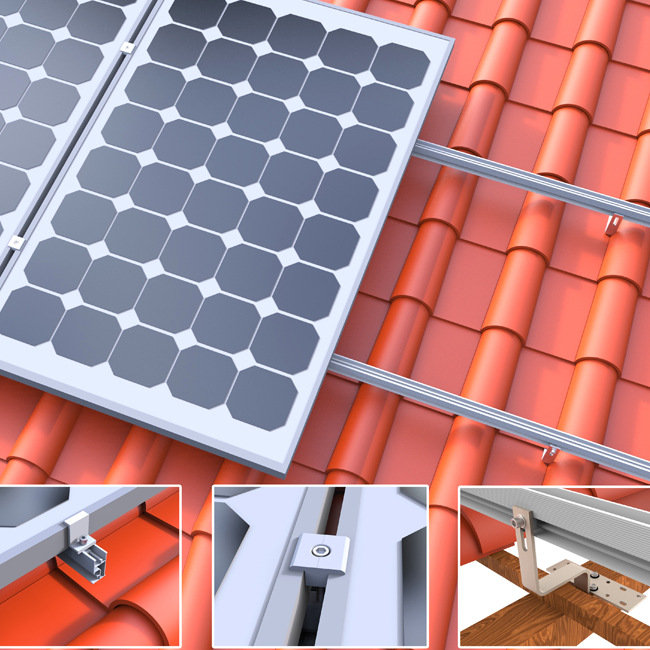

Aluminum L-Shaped Photovoltaic Corner Codes – Essential Mounting Components

The aluminum L-shaped photovoltaic corner code serves as a crucial auxiliary bracket component, designed for securing and installing solar panels.

Key Functions & Applications:

Typically used to connect solar panels to mounting structures

For frameless double-glass modules, it directly clamps the PV glass while linking to the bracket

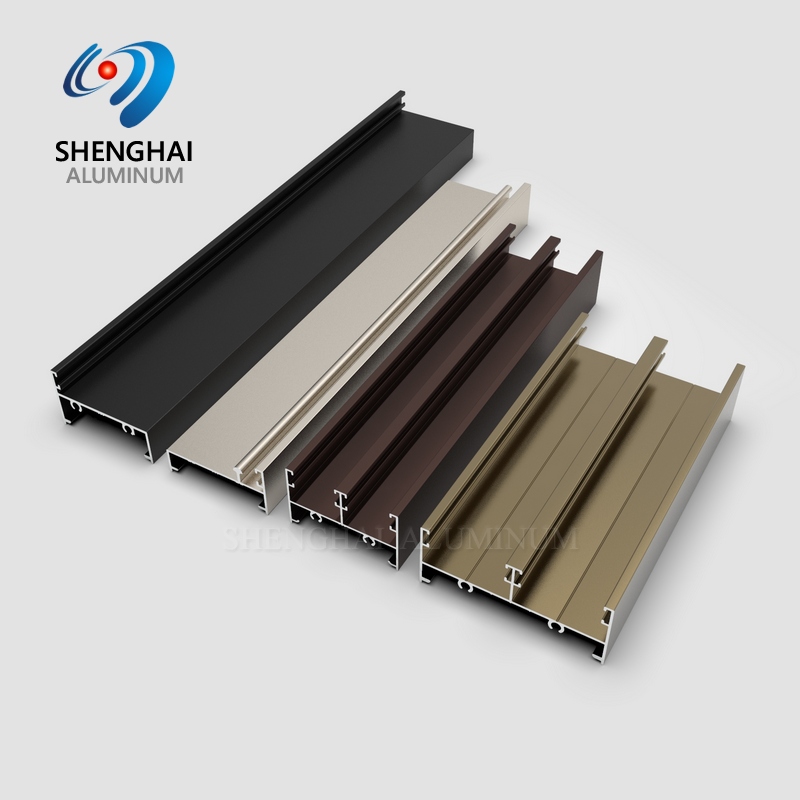

Material & Surface Treatment:

Constructed from high-grade 6063 aluminum alloy for durability and strength

Features anodized surface treatment for enhanced corrosion resistance

Comprehensive Solar Bracket Solutions:

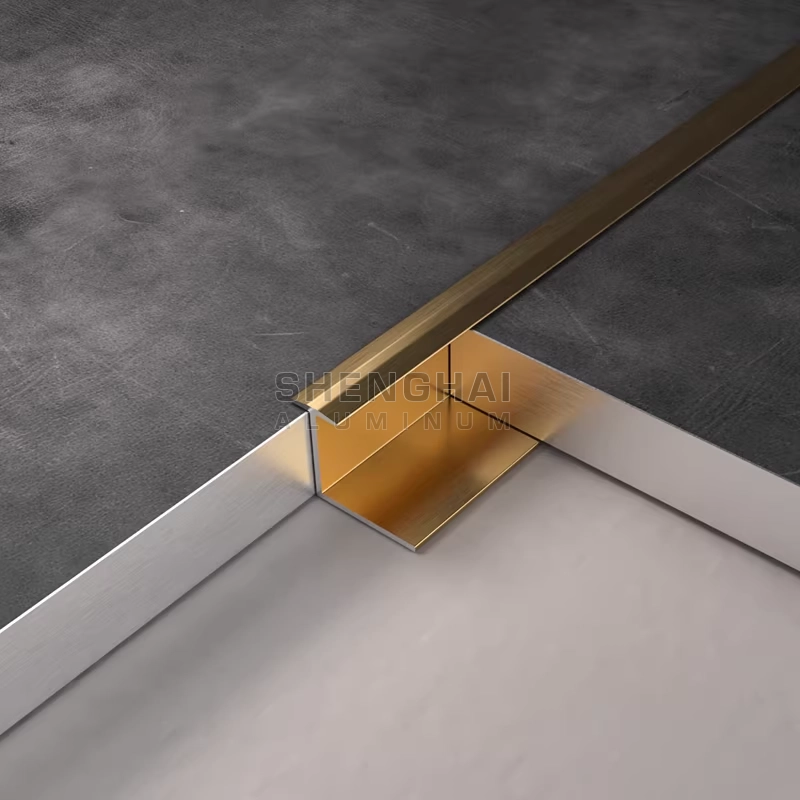

In addition to L-shaped corner codes, we offer:

✔ T-shaped corner codes

✔ Solar clamps

✔ Support corner codes

✔ Adjustable corner codes

Why Choose Sh-Extrusion?

One-stop supplier for all solar photovoltaic aluminum profiles and accessories

Custom manufacturing to reduce your costs and lead time

Optimize your solar mounting system with our precision-engineered components – contact us today!

Product Feature

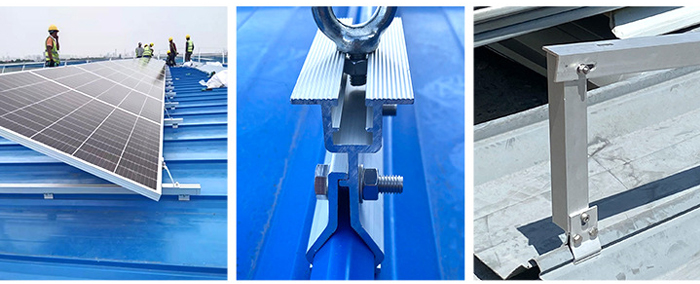

Product Application

Sh-Extrusion products are widely used in family residences, villas/high-end residences, office buildings/office buildings, hotels/shopping malls, schools/hospitals, airports/stations, factories/warehouses, industries and other scenarios, covering almost all building scene requirements.

The profiles, glass and hardware configurations can be adjusted according to specific scene requirements (such as regional climate, safety level, decoration style, etc.) to achieve the optimal solution.

Packaging Details

PE film for each profile/ Shrink PE film for each bundle, Slot packing, Craft paper/ Foam Paper/Carton box.