Aluminum Thermal Break Window For House

Product Description

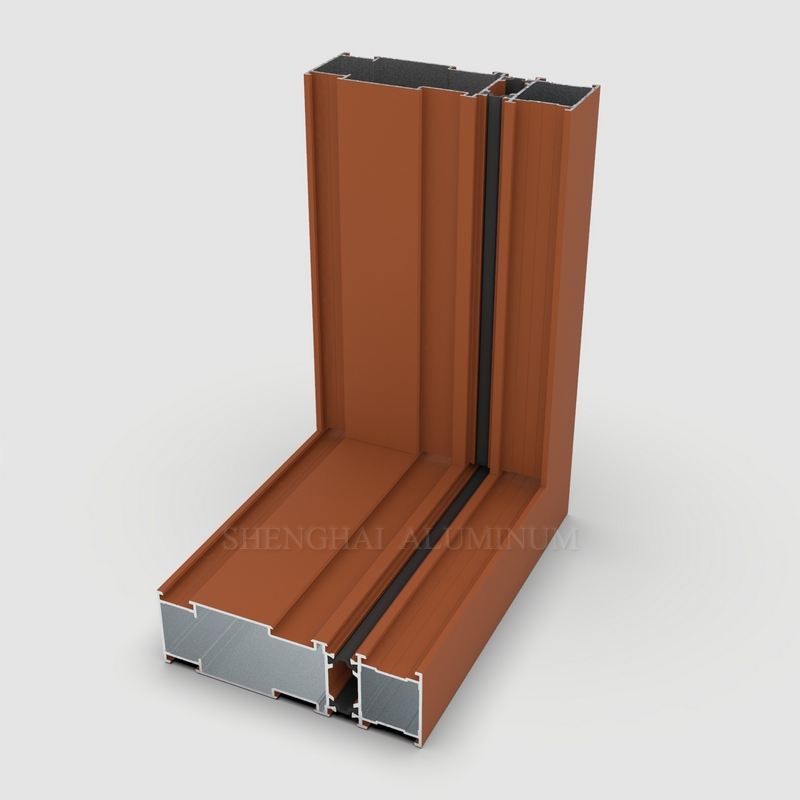

This aluminum thermal break is customized by an Oman customer for house windows. Aluminum profiles have good thermal break properties and are cost-effective, so they are best used to make thermal break door and window frames. The production process of broken bridge aluminum profiles is more complicated than that of ordinary ones. For example, it is necessary to add thermal broken strips to the aluminum profiles, assemble a double-layer aluminum structure, etc. Choosing an excellent broken bridge profile can achieve better thermal insulation, heat insulation, waterproof and dustproof effects for thermal break windows. Shenghai Aluminium has rich experience in extruded door and window profiles. If you want a quote, please get in touch with our sales team.

Product Features

1. Conducts heat and noise 1,000 times slower than standard aluminum

2. Non-flammable

3. The added layer of security

4. Low maintenance

5. Long-lasting

6. Durable

7. Non-Corrosive

8. Thermal break technology

9. Excellent thermal and acoustic insulation

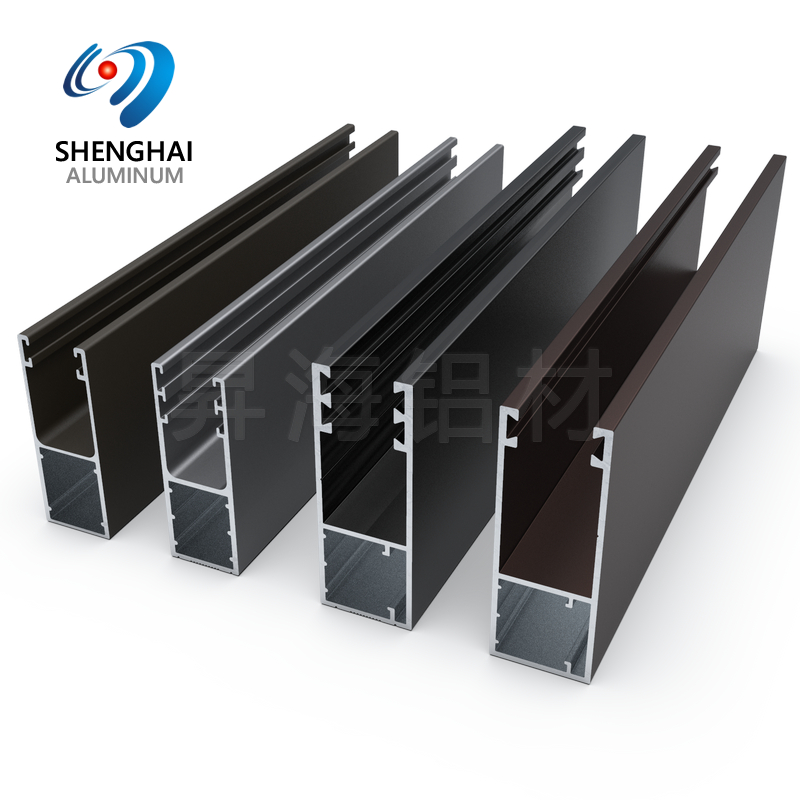

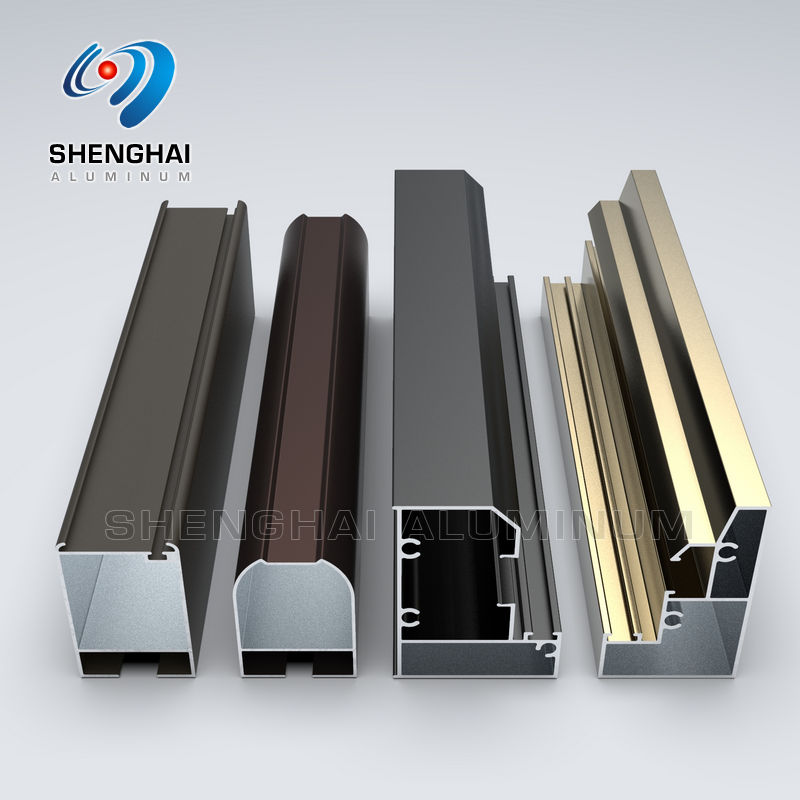

10. Powder coated surfaces in a variety of colors

Product Feature

Product Application

ShengHai aluminum products are widely used in family residences, villas/high-end residences, office buildings/office buildings, hotels/shopping malls, schools/hospitals, airports/stations, factories/warehouses, industries and other scenarios, covering almost all building scene requirements.

The profiles, glass and hardware configurations can be adjusted according to specific scene requirements (such as regional climate, safety level, decoration style, etc.) to achieve the optimal solution.

Packaging Details

PE film for each profile/ Shrink PE film for each bundle, Slot packing, Craft paper/ Foam Paper/Carton box.

Product Detail

| Material & Temper | Alloy 6063-T5,6061-T6 , We will never use aluminum scrap. |

|---|---|

| Surface Treament | Mill-Finished, Anodizing, Powder Coating, Electrophoresis, Wood Grain, Polishing, Brushing, etc. |

| Colour | Silver, Champage, Bronze, Golden, Black, Sand coating, Anodized Acid and alkali or Customized. |

| Film Standard | Anodized:7-23 μ , Powder coating: 60-120 μ , Electrophoresis film: 12-25 μ. |

| Lifetime | Anodized for 12-15 years outdoor, Powder coating for 18-20 years outdoor. |

| New Moulds | Opening new mould about 7-10 days, absolutely moulds cost can be refund. |

| Extrusion Machine | 600-3600 tons all together 6 extrusion lines. |

| Capability | Output 1200 tons per month. |

| Profile type | 1. Sliding window and door profiles; 2. Casement window and door profiles; 3. Aluminum profiles for LED light; 4. Tile Trim Aluminum profiles; 5. Curtain wall profile; 6. Aluminum heating insulation profiles; 7. Round/Square General profiles; 8. Aluminum heat sink; 9. Others Industry profiles. |

| Deep Processing | CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling |

| Fabrication | Die designing→ Die making→ Smelting & alloying→ QC→ Extruding→ Cutting→ Heat Treatment→ QC→ Surface treatment→ QC→ Packing→ QC→ Shipping→ After Sale Service |